Line items like orifice flanges, spectacle blinds, strainers, etc shall be installed following proper orientation. Installing Piping FlangesĬlean pipe flanges should be brought up flush and square without forcing to bear uniform bolt tension and gasket compression.

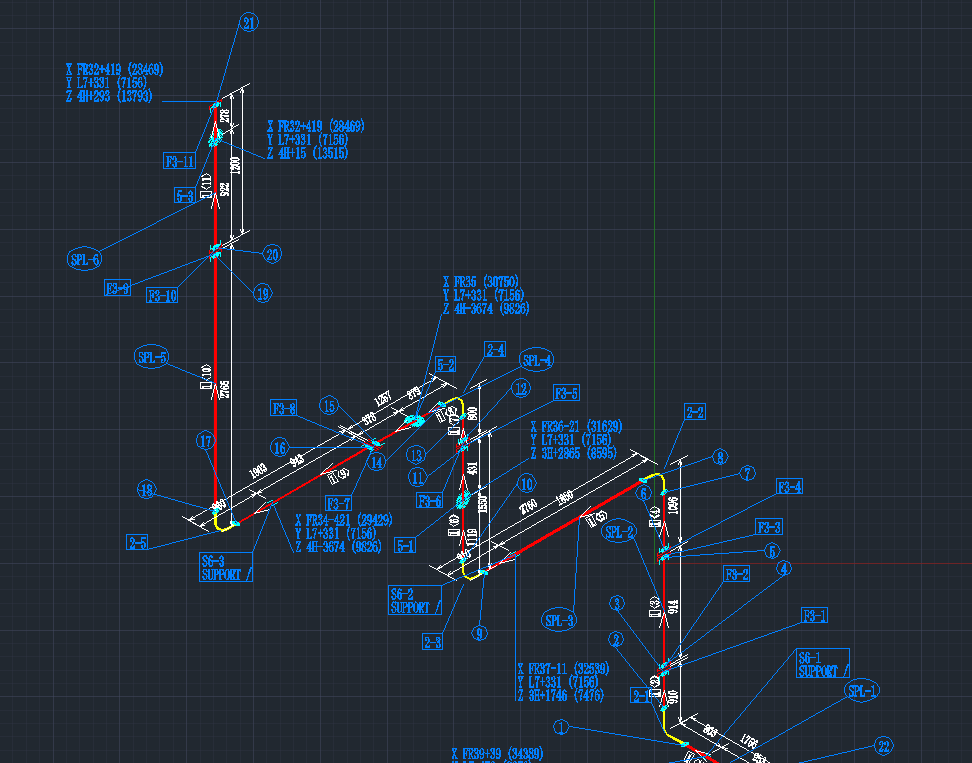

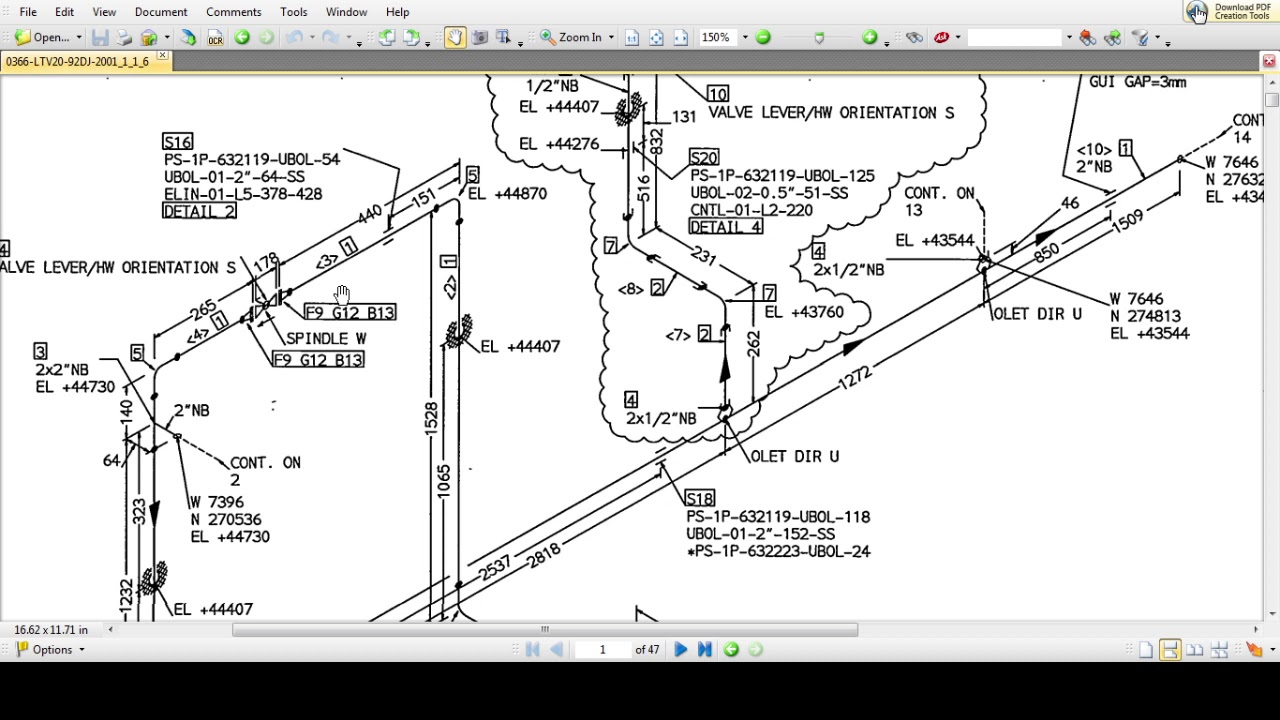

Proper planning should be made to erect piping, area-wise following piping isometric and GA drawings. Underground Pipe Installation Pipework Erection Procedure.Installing Piping Flanges, Valve, and equipment Flange Connection.1 below shows typical drawings required for piping installation and a piping erection and installation flow chart. Piping GA drawings include the locations of the main equipment in the plant, main piping items, fittings and valves, nozzle orientation of the concerned equipment, etc. Piping Isometric drawings include proportionate drawings with exact dimensions represented, line numbers, pipe fittings, valves, flanges, special components, tables including a list of all fittings in the drawings, etc. Process condition & physical data, operation condition, streamflow details, Equipment numbers, etc. P&ID is considered to be the heart of piping, they include pipeline number, size, material, and insulation. Piping Support Drawings from Pipe Support Standard.

The main inputs referred to during piping erection are:

Piping installation at the construction site is done following proper engineering work methods and drawings.

0 kommentar(er)

0 kommentar(er)